Crawler Scissor Lift HC1416E-R

The HERED HC1416E-R is an electrically driven crawler-type scissor lift platform designed for aerial work, featuring a maximum platform height of 13.8 meters, a maximum working height of 15.8 meters, and a rated load capacity of 250 kg. Equipped with a crawler chassis, it excels in off-road maneuverability and climbing ability. Its large-capacity battery allows for extended emission-free operation. The following analysis covers detailed parameters, main features, optional configurations, applicable scenarios, and structural layout.

Platform Capacity

Max. Working Height

1. Compact structure, light weight, accessible elevators.

2. Motor and crawler drive, lower noise, stronger passability.

3. Large capacity batteries, better endurance.

Key Features and Advantages

The HC1416E-R Crawler Scissor Lift incorporates multiple standout design elements that contribute to its excellent performance and operational benefits:

Pure Electric Drive – Zero Emissions & Low Noise

The electric motor powers the hydraulic system, resulting in zero exhaust emissions for an environmentally friendly and clean operation. It runs with extremely low noise levels, making it ideal for indoor use or quiet environments. The all-electric system also delivers smooth power output, ensuring stable operation and reduced maintenance requirements.

Crawler Chassis – Strong Off-Road Capability

The crawler travel system offers outstanding terrain adaptability and traction. It can traverse soft or uneven surfaces such as mud, grass, or gravel without getting stuck. With 300mm-wide tracks, ground pressure is minimized, protecting surface integrity. Additionally, the machine boasts a 40% gradeability, allowing it to climb steep slopes with ease.

Zero-Turn Steering – Agile Maneuverability

The dual-track design enables zero turning radius for on-the-spot rotation, allowing the machine to reposition easily even in tight or complex job sites. This is especially advantageous for aerial tasks in confined areas or when frequent repositioning is needed.

Compact Design – Easy Maintenance

The machine’s compact layout features a clean structure, with key components such as batteries, motors, and hydraulic elements arranged for easy access and maintenance. Foldable guardrails make transportation and storage more convenient (folded height is only 2.01m). The overall weight is lighter than comparable models, facilitating lifting and towing. The simplified design also means fewer failure points and easier upkeep.

Long Endurance – High-Capacity Battery

Equipped with a high-capacity battery pack (48V/300Ah), the lift supports extended continuous operation on a single charge. This ensures that it can work through a full 8-hour shift without frequent recharging, enhancing job site productivity. The battery system includes overcharge protection and a power level display for timely charging.

Multiple Safety Features

The HC1416E-R is equipped with a full safety system, including automatic brakes, anti-tilt protection, emergency stop, and emergency descent functions. If the machine operates outside safe conditions (e.g., beyond allowable tilt angles), tilt sensors will trigger alarms and prevent lifting to ensure operator safety. The platform includes a self-locking gate to prevent accidental falls, while the hydraulic system features rupture protection to prevent sudden pressure loss and platform drop. These comprehensive safety features ensure reliable and secure aerial operation.

These features enable the HC1416E-R to perform safely and efficiently across a wide range of complex environments while providing maximum convenience to the operator.

Optional Configurations and Attachments

To meet the diverse needs of clients and working conditions, the HC1416E-R offers a range of optional configurations and attachments that enhance its versatility and operational efficiency:

Platform Work Lights: Lighting installed on the platform rails to illuminate the work area during night operations or in low-light conditions, ensuring safety and precision.

Load Sensing System: Automatically detects the platform load and prevents overloading. If the weight exceeds the rated capacity, an alarm is triggered or operation is limited to protect both personnel and equipment.

AC Power Outlet (to Platform): Provides 220V/110V AC power directly to the platform, allowing workers to operate electric tools such as drills or welding machines at height without dragging long extension cords, improving efficiency.

Compressed Air Line (to Platform): Adds a pneumatic connection to the platform for operating air-powered tools or spray equipment. This is particularly useful for using air wrenches or spray guns at height, reducing the risk of suspended hoses.

These options can be installed as needed. Mounting points are pre-reserved at the factory, making upgrades or installations simple and efficient. These attachments expand the machine’s capabilities and enhance the HC1416E-R’s adaptability for specialized applications.

Application Scenarios

Thanks to its crawler-based off-road capabilities, clean electric power, and reliable aerial work performance, the HC1416E-R is well-suited for a wide range of ground conditions and industry applications:

Rugged Terrain and Outdoor Construction Sites

Construction and infrastructure sites such as building projects and bridge maintenance often involve uneven terrain, including mud, gravel roads, or slopes. The crawler drive system and automatic outrigger leveling allow the lift to operate stably on rough ground. For example, during façade installation or steel structure assembly, the HC1416E-R can climb moderate slopes and provide a steady platform for operators to reach their working height.

Municipal Maintenance and Landscaping

Tasks such as streetlight maintenance, traffic signal repair, or tree trimming often require operation over grass or soft soil. The HC1416E-R’s low ground pressure tracks prevent it from sinking into lawns or mud, minimizing surface damage and enabling direct access to the work site. Its zero emissions and low noise operation also make it ideal for use in urban streets and residential areas without causing pollution or disturbance.

Indoor Large Spaces and Industrial Facilities

In spacious indoor environments such as factories, airport hangars, and stadiums, aerial work platforms are needed for installation and maintenance tasks. However, floors in such areas may be unfinished or delicate. The crawler lift spreads its weight to avoid damaging sensitive surfaces while providing stable movement. Its electric drive system produces no exhaust, making it safe for enclosed indoor use (provided the floor supports its weight). Common applications include pipe maintenance in workshops or servicing high storage racks in warehouses.

Petrochemical, Energy, and Special Environments

In hazardous environments like petrochemical plants and mining areas where flammable materials are present, internal combustion equipment poses risks due to exhaust and sparks. The HC1416E-R’s electric drive eliminates these dangers, making it a safer choice. Its off-road capability also allows it to operate on gravel in mining sites or sandy roads in oil fields for inspection and repair tasks. The equipment is certified to safety standards such as CE and ANSI, ensuring it meets the strict requirements of high-risk environments.

In summary, the HC1416E-R is highly adaptable to both indoor and outdoor scenarios, especially where ground conditions are challenging or environmental restrictions are tight. From construction sites and factory maintenance to municipal projects and landscaping, this crawler scissor lift offers a safe and efficient solution for aerial work in diverse industries.

Configurations

Standard

Automatic Braking, Extension Platform, Floding Guardrails, Charging Protection, Emergency Stop Tilt Sensor, Safety Arm, Self-diagnosis, Platform Self-lock Door, Flashing Beacons, Emergency Descent, Hour Meter, Motion Alarm, Horn

Optional

Working Lamp on the Platform, Load Sensing System, AC Power to the Platform, Air Pipe to the Platform

| MODEL | HC1416E-R |

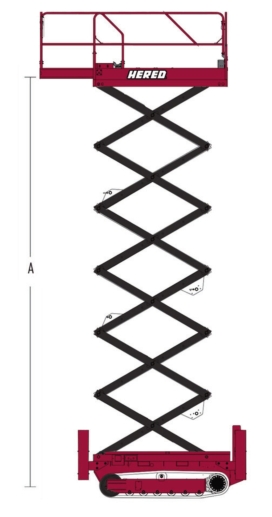

| A-Max. Platform Height(In/out) | 13.8m/13.8m |

| Max. Working Height(In/out) | 15.8m/15.8m |

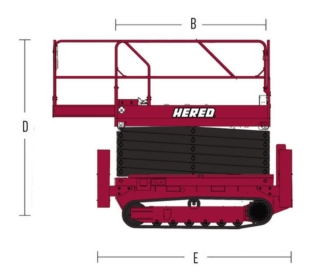

| B-Platform Length | 2.64m |

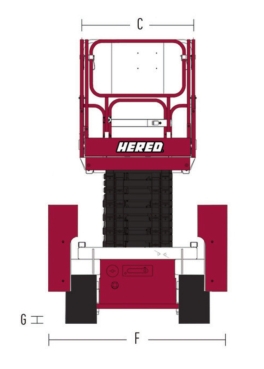

| C-Platform Width | 1.12m |

| Extension Size | 0.9m |

| D-Heights (Rails Up) | 2.71m |

| Height (Rails Down) | 2.01m |

| E-Overall Width with Outriggers | 3.02m |

| F-Overall Width | 1.6m |

| G- Ground Clearance | 146mm |

| PERFORMANCE | |

| Platform Capacity | 250kg |

| Extension Capacity | 113kg |

| Max. Occupancy(in/out) | 2/2 |

| Max.Wind Speed | 12.5m/s |

| Drive Speed (Stowed) | 2.5km/h |

| Turning Radius | Rotate in Place |

| Up/Down Time | 76/53s |

| Gradeability | 40% |

| Max. Slope | / |

| Leveling angle of the legs | 12°/5° |

| Drive | Rear Crawler |

| Crawler (mm) | 300mmX101mmX48 |

| POWER | |

| Batteries (V/Ah) | 8X6V/200Ah |

| Charger | 100-240VAC/13.5A |

| WEIGHT | |

| Weight | 4150kg |

Based on the above specifications, the HC1416E-R features a platform height of 13.8 meters and a working height of 15.8 meters. The platform measures 2.64 × 1.12 meters and includes a 0.9-meter extension deck to expand the working area. The overall machine width is only 1.6 meters (with a folded guardrail height of 2.01 meters), making it easy to pass through narrow passages. During operation, the four outriggers can be extended to increase the support width to 3.02 meters, ensuring stability at height. The equipment has a rated load capacity of 250 kg, with 113 kg on the extension platform, allowing two people to work simultaneously. It features a 40% gradeability and zero-turning radius, making it suitable for sloped surfaces (the outriggers can level up to 12° front/rear and 5° left/right). It is powered by a large-capacity 8×6V/300Ah battery pack that drives the motor and hydraulic system, and is equipped with an adaptive wide-voltage charger. The total machine weight is approximately 4.15 tons, with weight concentrated on the chassis to lower the center of gravity and enhance stability.

Structure and Layout Features

As illustrated in the diagram, the HC1416E-R adopts a lower chassis layout with tracks and hydraulic outriggers, while the upper structure consists of a scissor lift mechanism. The rubber tracks on both sides of the chassis provide stable mobility support. The drive wheels are positioned at the rear and the guide wheels at the front, ensuring powerful traction and reliable braking performance. Each track runs the full length of the chassis frame, distributing weight more evenly and reducing ground pressure on soft terrain.

At the four corners of the chassis, integrated hydraulic outriggers (shown as red vertical legs in the diagram) can be deployed to increase the contact width up to 3.02 meters and automatically level the entire machine. This ensures the platform remains vertical even on sloped or uneven ground. When the outriggers are retracted, the machine’s width is only 1.6 meters, allowing it to pass through narrow doorways and corridors. The compact and robust layout of the outriggers and chassis makes maintenance easy while providing a stable low center of gravity for the upper scissor lift mechanism.

The upper platform features a multi-stage scissor arm structure made from high-strength steel, allowing vertical lifting of the work platform. Powered by hydraulic cylinders, the scissor arms extend to raise the platform up to a maximum height of 13.8 meters. When fully retracted, the machine’s height is just 2.01 meters (with the guardrails folded), making it easy to navigate low-clearance areas and for transport and storage.

The platform area measures 2.64 × 1.12 meters, large enough to accommodate two workers along with their tools. One side of the platform includes a 0.9-meter extendable deck, which can be pulled out on a rail system to help reach over obstacles or get closer to walls. The platform is equipped with foldable guardrails, safety self-locking gates on all sides to prevent falls, and high-visibility red coating with warning labels for added safety on-site. A mechanical safety support bar is located beneath the platform, which can be inserted to hold the scissor structure during maintenance to prevent accidental descent.

The control system is also optimized for ergonomic operation. Control panels are available at both the chassis base and on the platform, enabling dual-position operation from the ground and at height. The system supports proportional control, allowing operators to precisely adjust driving and lifting speeds with the joystick based on tilt angle, ensuring smooth starts and stops. The electrical system features self-diagnosis, displaying fault codes via indicators or screens for quick troubleshooting. The standard automatic braking and parking brake system ensures the machine remains stationary on inclines. Additionally, a built-in GPS module enables real-time positioning and remote monitoring, aiding fleet management and theft protection.

In summary, the HC1416E-R's structural design fully addresses the stability and usability demands of aerial work platforms. The tracked chassis offers a stable base for mobility, while hydraulic outriggers ensure secure operation at height. The robust scissor mechanism provides reliable vertical lifting, and the spacious, extendable platform enhances working efficiency. Coupled with well-organized hydraulic and electrical systems and comprehensive safety features, the HC1416E-R delivers a balance of easy maintenance, low center of gravity, strong terrain capability, and high safety, making it a highly capable solution for aerial tasks in challenging environments.

Related Products

Submitted successfully

We will contact you as soon as possible